pipe rolling mill

Jan . 14, 2025 11:17

Back to list

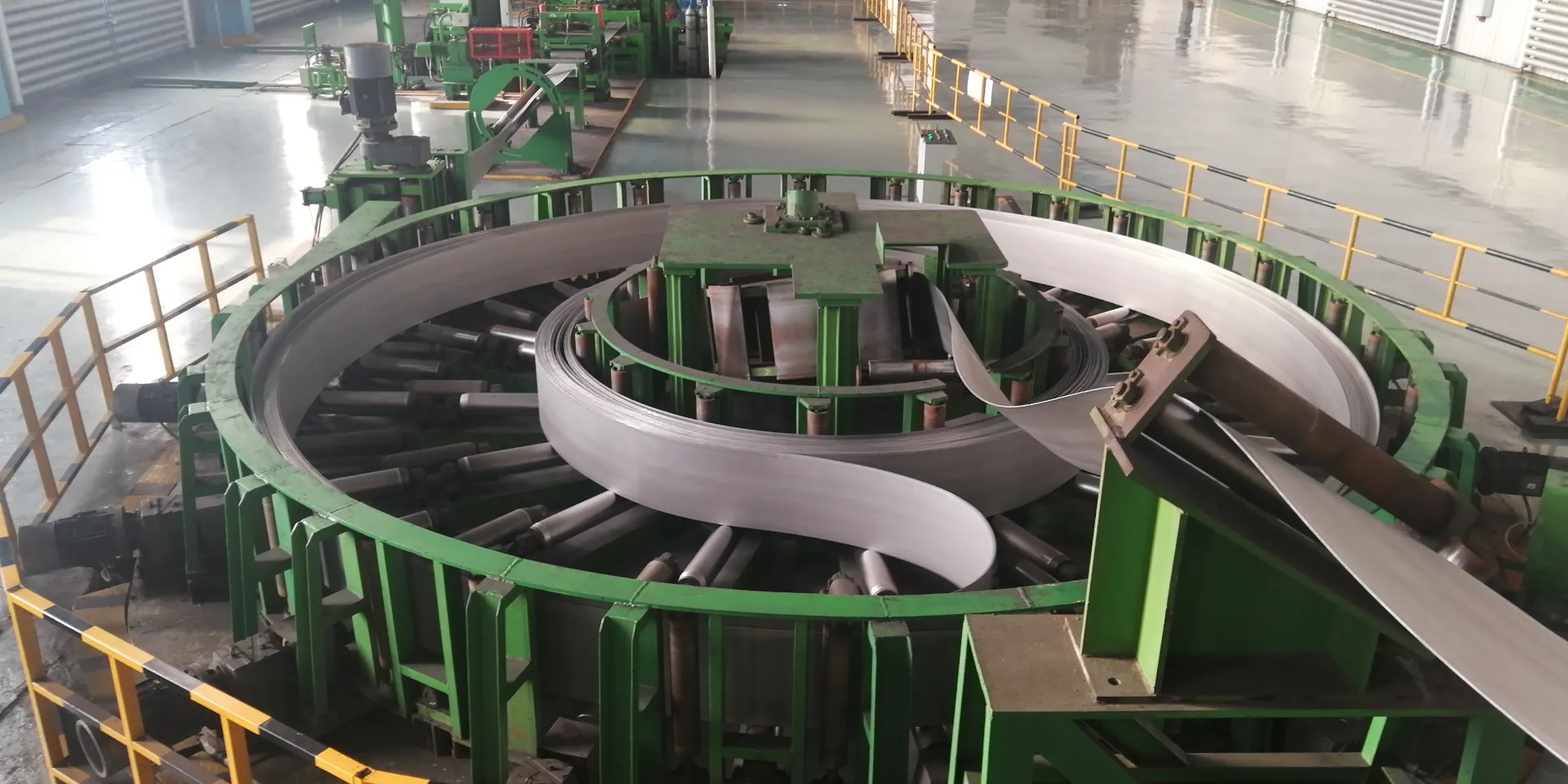

pipe rolling mill

Pipe rolling mills represent a sophisticated blend of engineering prowess, technological innovation, and manufacturing expertise, playing an indispensable role in the production of seamless steel pipes. At the heart of major industries, these mills transform raw metal into precision-engineered pipes that meet exacting standards required by sectors ranging from construction to oil and gas.

Authoritativeness in the manufacturing space demands stringent adherence to environmental and industry regulations. Pipe rolling mills today are increasingly focusing on sustainability, employing energy-efficient methods and reducing waste within the production cycle. Through innovative recycling techniques and heat recovery systems, these mills contribute to a smaller carbon footprint, aligning with global environmental goals. The expertise embedded in the operations of pipe rolling mills is underscored by a workforce adept in both traditional techniques and modern technologies. Ongoing training and development ensure that operators are knowledgeable in the latest advances, from material science to digital manufacturing, maintaining a high standard of output that customers have come to trust. Trustworthiness emerges not only from the quality of the pipes produced but also from the reliability of the production process. Regular audits, certifications, and compliance with international standards such as ISO and ASTM reinforce the commitment of these mills to produce superior products. Clients worldwide rely on the guaranteed performance, longevity, and safety of pipes crafted by these mills, building longstanding partnerships based on trust and performance. In summary, the modern pipe rolling mill is a bastion of innovation, expertise, and reliability, essential to the continuous advancement of global infrastructure. By maintaining stringent quality controls, employing efficient production methods, and fostering a culture of continuous improvement, these mills ensure they meet the evolving needs of a demanding market while also steering towards a more sustainable future.

Authoritativeness in the manufacturing space demands stringent adherence to environmental and industry regulations. Pipe rolling mills today are increasingly focusing on sustainability, employing energy-efficient methods and reducing waste within the production cycle. Through innovative recycling techniques and heat recovery systems, these mills contribute to a smaller carbon footprint, aligning with global environmental goals. The expertise embedded in the operations of pipe rolling mills is underscored by a workforce adept in both traditional techniques and modern technologies. Ongoing training and development ensure that operators are knowledgeable in the latest advances, from material science to digital manufacturing, maintaining a high standard of output that customers have come to trust. Trustworthiness emerges not only from the quality of the pipes produced but also from the reliability of the production process. Regular audits, certifications, and compliance with international standards such as ISO and ASTM reinforce the commitment of these mills to produce superior products. Clients worldwide rely on the guaranteed performance, longevity, and safety of pipes crafted by these mills, building longstanding partnerships based on trust and performance. In summary, the modern pipe rolling mill is a bastion of innovation, expertise, and reliability, essential to the continuous advancement of global infrastructure. By maintaining stringent quality controls, employing efficient production methods, and fostering a culture of continuous improvement, these mills ensure they meet the evolving needs of a demanding market while also steering towards a more sustainable future.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products