4 High Skin Pass Mill for Superior Surface Quality Advanced 6 High & 1700 Skin Pass Mill Solutions

- Introduction to the Scope and Technology of 4 High Skin Pass Mills

- Comparative Overview of 4 High, 6 High, and 1700 Skin Pass Mills

- Technical Features, Process Data, and Operating Parameters

- Vendor Comparison: Global Market Leaders and Their Key Differentiators

- Customization Capabilities and Tailored Solutions for Industrial Partners

- Case Studies: Performance in Real-World Applications

- Conclusion: The Evolving Landscape of the 4 High Skin Pass Mill Market

(4 high skin pass mill)

Introduction to 4 High Skin Pass Mill Technologies

The 4 high skin pass mill

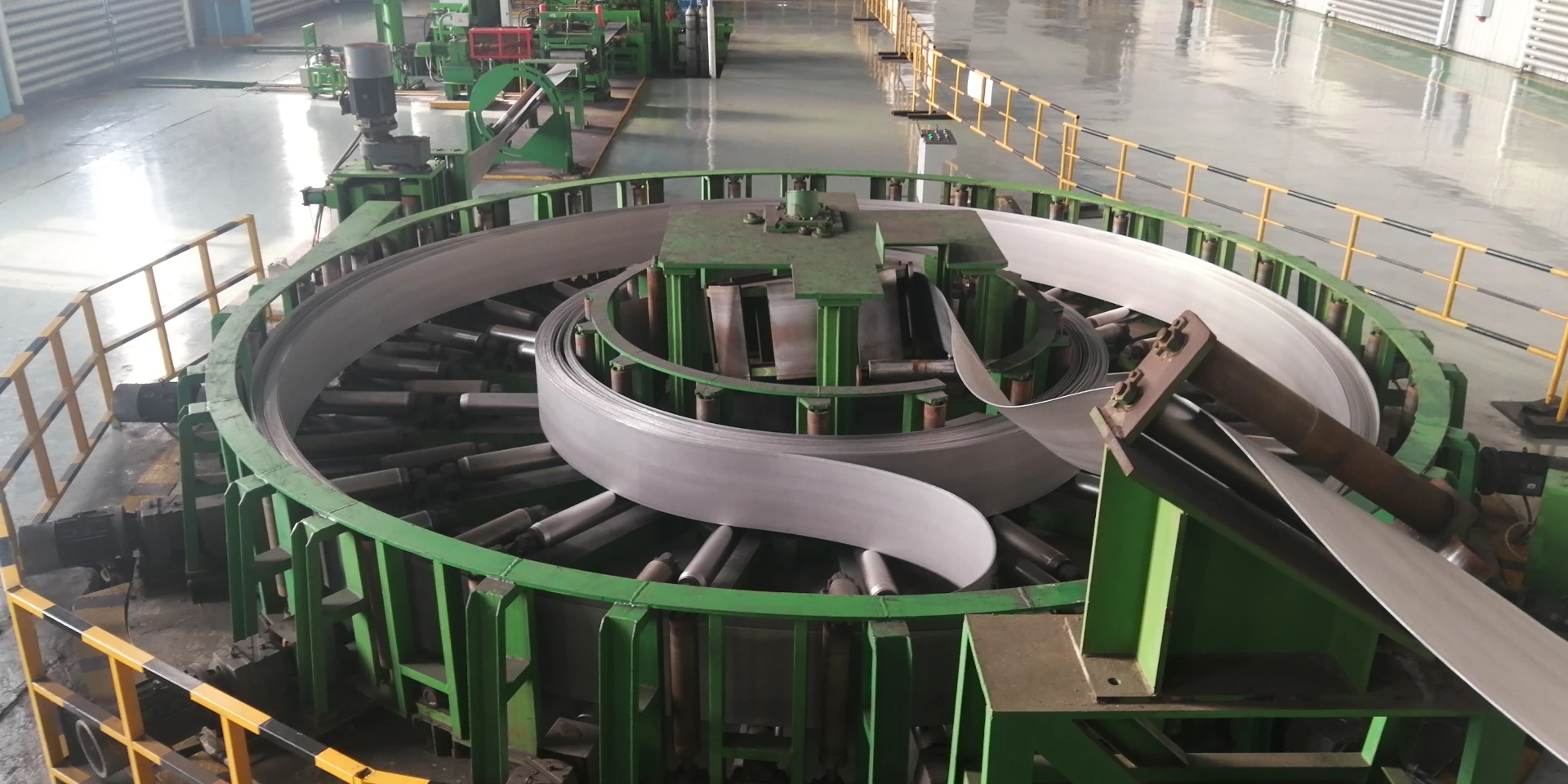

plays a pivotal role in the steel finishing industry by delivering enhanced surface properties and improved flatness to cold-rolled strip products. Modern skin pass mills, especially the 4 high configuration, are engineered to deliver precise elongation and optimal surface texture, essential for subsequent coating and forming processes. Unlike conventional rolling mills, the 4 high skin pass mill utilizes two smaller work rolls supported by two larger backup rolls, ensuring high performance with minimal deflection and uniform pressure distribution. This setup is fundamental for reaching tight thickness tolerances and desired yield points, crucial in end-user industries like automotive, appliances, and construction.

Recent advancements in mill design underscore a shift towards greater automation, real-time monitoring, and digital integration, driving efficiency and consistency. Given the increasing demand for ultra-flat, high-quality steel with superior surface finish, manufacturers are turning to innovative solutions within skin pass technology for competitive advantage.

Comparative Analysis: 4 High, 6 High, and 1700 Skin Pass Mills

The skin pass mill family encompasses several configurations, with 4 high, 6 high, and wide-width options such as the 1700 skin pass mill addressing different technical and operational requirements. The 6 high skin pass mill, for instance, introduces an additional pair of intermediate rolls, facilitating even finer control over strip shape and reduced edge drops compared to the 4 high. The 1700 skin pass mill, named for its millimeter-wide strip processing capability, exemplifies the demands for large-scale coil finishing in global markets.

The comparative table below highlights key differences among the major types of skin pass mills to clarify their operational strengths and ideal industrial fit.

| Specification | 4 High Skin Pass Mill | 6 High Skin Pass Mill | 1700 Skin Pass Mill |

|---|---|---|---|

| Typical Work Roll Diameter (mm) | 400-600 | 300-600 | 540-700 |

| Max Strip Width (mm) | 1700 | 1850 | 1700 |

| Mill Stand Configuration | 2 Work + 2 Backup Rolls | 2 Work + 2 Intermediate + 2 Backup | 2 Work + 2 Backup Rolls |

| Elongation Range (%) | 0.5–3.0 | 0.5–2.5 | 0.5–2.5 |

| Strip Thickness In/Out (mm) | 0.2-3.0 / 0.15-2.5 | 0.15-2.5 / 0.12-2.3 | 0.2-2.8 / 0.17-2.5 |

| Automation Level | Established | Advanced | High |

| Main Application | Automotive, Home Appliance, General Industry | Precision, High Surface Requirement | Large Scale Coil Processing |

These data-driven distinctions enable decision-makers to select the optimal mill based on throughput, product specification, and downstream requirements, further highlighting the unique role of each configuration.

Technical Features and Operating Parameters

Skin pass mills achieve their performance targets through several key technologies and parameters. The 4 high skin pass mill’s mechanical robustness is complemented by advanced hydraulic roll gap controls, highly sensitive pressure sensors, and digital drive systems. The addition of work roll bending systems allows for minute adjustments to roll profiles during operation, directly influencing strip flatness. In practice, typical line speeds for modern 4 high models range from 400 to 1200 meters per minute, supporting high-throughput, continuous operations.

Surface roughness, usually set between 0.6 to 2.5 μm Ra, is achieved through precisely textured rolls and stable lubrication systems. Elongation uniformity, crucial for yield strength tuning, is controlled within ±0.05% through a feedback-controlled hydraulic system. Real-time monitoring of shape, thickness, and temperature is integral, with digital control systems reducing required setup times by up to 30%. These features ensure that the mill not only delivers physical enhancement but also supports strict metallurgical demands.

Maintenance downtime has dropped substantially, with predictive maintenance solutions cutting unplanned stoppages by 15–20% over legacy systems. Integration with plant MES (Manufacturing Execution System) modules streamlines scheduling, traceability, and just-in-time manufacturing, ensuring the mill’s relevance in high-paced, quality-driven production environments.

Vendor Comparison: Global Manufacturers and Differentiators

The global skin pass mill market is led by a handful of highly specialized vendors, each offering unique technological advantages, regional support, and customization capabilities. Leading suppliers, including SMS group (Germany), DANIELI (Italy), Primetals Technologies (Austria-Japan), and ANDRITZ (Austria), represent the cutting edge in terms of mill design, control systems, and integration with upstream/downstream processing.

| Vendor | Region | Innovative Features | Global Installations | Service Ecosystem |

|---|---|---|---|---|

| SMS Group | Europe, Asia, Americas | Eco-efficient stand design, advanced automation, roll service | 400+ | Global, 24/7 digital service platform |

| DANIELI | Worldwide | Quick-change system, AI-assisted controls | 300+ | Global, regional training centers |

| Primetals Technologies | Europe, Asia | Hybrid drive system, integrated MES link | 250+ | On-site/remote hybrid model |

| ANDRITZ | Europe, Americas | Heavy-duty housing, energy optimization | 180+ | On-call support, digital twins |

Selecting the right vendor often hinges on the intended product mix, target capacity, and the depth of digital integration required. Market leaders differentiate themselves through quick-response global support, sophisticated digital twins for process optimization, and continuous investment in R&D.

Customization and Tailored Solutions

Recognizing the diversity of end-use industries and material characteristics, skin pass mill manufacturers offer extensive customization options. These span from customized roll textures meeting specific automotive or appliance requirements to integration with upstream pickling lines and downstream galvanizing or annealing facilities.

Tailored automation packages allow precise monitoring of critical metrics—shape, surface finish, elongation—thus supporting complex product portfolios and frequent changeovers. For example, advanced roll polishing systems can shorten roll maintenance cycles by 40%, while modular control upgrades support Industry 4.0 standards, offering predictive analytics and actionable process insights.

High-capacity 4 high skin pass mills are often specified for large-scale service centers, while compact 6 high or 1700 skin pass mills fit operations with specialized output or stringent surface demands. The possibility of retrofitting legacy mills with modern controls and drive systems enhances ROI for established plants, while new installations benefit from end-to-end digital commissioning.

Application Cases: Real-World Implementation and Performance

Across the globe, implementation of skin pass mills has demonstrated tangible gains in productivity, product quality, and operational efficiency. For example, an automotive-grade steel producer in South Korea achieved a 25% reduction in coil rejections and improved flatness consistency after commissioning a new generation 4 high skin pass mill. This translated into shorter roll change cycles and substantial cost savings.

In Europe, an appliance manufacturer sought to diversify its sheet product range. The deployment of a flexible 6 high line enabled the production of high-gloss strips with a reduced roughness deviation (±0.03 μm Ra), significantly enhancing the visual appeal and deep-drawability of finished appliances. Similarly, a service center in North America processed wide coils using a 1700 skin pass mill at line speeds exceeding 900 meters per minute, scaling output to meet tight delivery deadlines for electrical steel used in transformers.

These application cases highlight the adaptability and measurable gains skin pass technology brings to sectors where quality, reliability, and economics go hand in hand. Integration with process data analytics platforms further sharpens process control, ensuring continuous performance improvement and defect traceability.

Conclusion: Future Trends in the 4 High Skin Pass Mill Market

The 4 high skin pass mill continues to be at the forefront of finishing technology, balancing tradition with emerging digital and material innovations. As the industry moves towards smarter factories and zero-defect production, expect further evolution in automation, inline quality assessment, and sustainable design. Data-driven operations, combined with flexible machine architectures, ensure the 4 high model remains indispensable for manufacturers emphasizing quality and operational excellence.

Looking ahead, sustainability will be a significant differentiator, with energy-efficient designs and reduced resource consumption shaping investment priorities. Close collaboration between equipment suppliers and industrial partners will drive customization, onboarding of new digital solutions, and ongoing optimization in line with market and regulatory demands.

(4 high skin pass mill)

FAQS on 4 high skin pass mill

Q: What is a 4 high skin pass mill?

A: A 4 high skin pass mill is a type of rolling mill that uses four rolls—two working rolls and two backup rolls. It is mainly used to improve the surface finish and mechanical properties of metal strips. This process also helps in achieving desired flatness and elongation.Q: How does a 4 high skin pass mill differ from a 6 high skin pass mill?

A: A 6 high skin pass mill has two additional intermediate rolls compared to the 4 high version. These extra rolls help reduce roll bending and improve gauge accuracy. As a result, the 6 high mill provides better flatness and thickness control.Q: What materials are commonly processed in a 1700 skin pass mill?

A: A 1700 skin pass mill typically processes carbon steel, stainless steel, and sometimes aluminum coils. The "1700" typically refers to the mill width in millimeters. This equipment is used particularly in finishing lines of steel and aluminum plants.Q: What are the main benefits of using a 4 high skin pass mill?

A: The 4 high skin pass mill enhances strip flatness, improves surface brightness, and offers better mechanical properties. It also helps remove yield point elongation in steel products. This results in higher quality for downstream processing.Q: Can a 6 high skin pass mill be used for the same applications as a 4 high skin pass mill?

A: Yes, a 6 high skin pass mill can be used for similar applications, including improving surface finish and flatness. However, it offers better control over thickness and flatness due to its more advanced roll configuration. It is preferred for materials requiring stricter quality tolerances.-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025