water quenching

Fév . 02, 2025 02:57

Back to list

water quenching

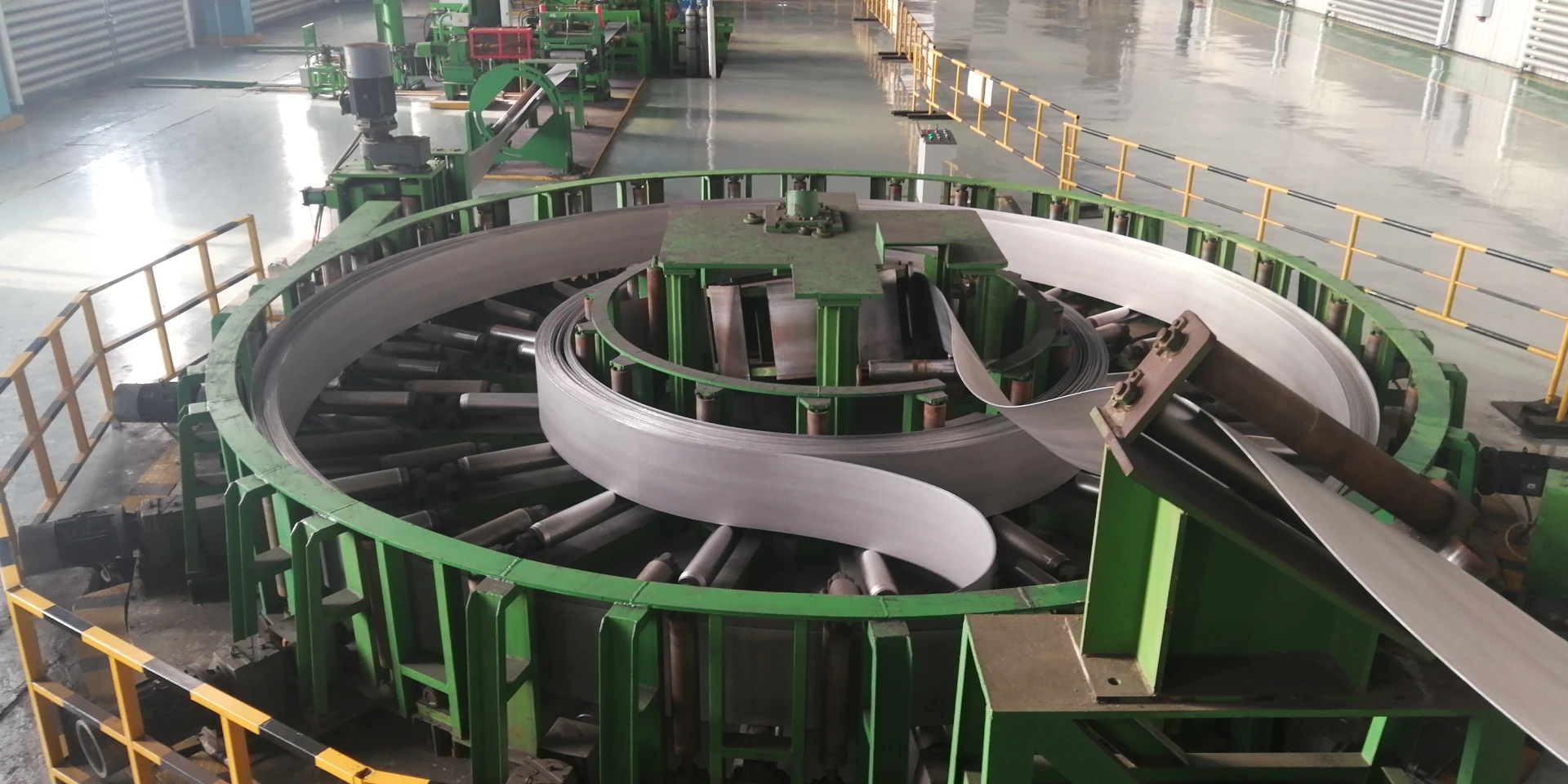

The engineering marvel known as the 3-high rolling mill is a pivotal innovation in the metalworking industry. Incorporating unmatched craftsmanship and technology, this mill is designed for efficiency and precision in shaping metal materials. As an industry expert, it's crucial to delve into the operational mechanics, benefits, and critical applications of this equipment to better appreciate its role in modern manufacturing processes.

The authority of a 3-high rolling mill in the manufacturing world extends beyond its raw metal processing abilities. Its application in producing sheets, bars, and sections required in automotive, construction, and aerospace industries signifies its integral role. Products crafted with such precision meet stringent industry standards, reinforcing the mill’s credibility and reliability. The expertise required to select the right rolling parameters for diverse applications further affirms the mill's established place in industry narratives. Trustworthiness is key in any industrial setup, and the 3-high rolling mill excels in this area due to its durability and minimal maintenance needs. The sturdy construction and use of high-grade materials in its manufacturing ensure longevity and less frequent breakdowns. Regular maintenance schedules, combined with prompt attention to operational components, can significantly extend the lifespan of the mill. This reliability fosters confidence among manufacturers, knowing their rolling process will remain uninterrupted and efficient. In conclusion, the 3-high rolling mill is much more than just a piece of equipment; it is an embodiment of engineering ingenuity that enhances productivity, precision, and profitability in metalworking industries worldwide. Leveraging its advantages requires a balance between technical knowledge and practical application, skills that can only be honed through experience and dedication to the field. As the industry progresses, staying abreast with advances in rolling technologies is essential in maintaining competitiveness and meeting the ever-evolving demands of the market.

The authority of a 3-high rolling mill in the manufacturing world extends beyond its raw metal processing abilities. Its application in producing sheets, bars, and sections required in automotive, construction, and aerospace industries signifies its integral role. Products crafted with such precision meet stringent industry standards, reinforcing the mill’s credibility and reliability. The expertise required to select the right rolling parameters for diverse applications further affirms the mill's established place in industry narratives. Trustworthiness is key in any industrial setup, and the 3-high rolling mill excels in this area due to its durability and minimal maintenance needs. The sturdy construction and use of high-grade materials in its manufacturing ensure longevity and less frequent breakdowns. Regular maintenance schedules, combined with prompt attention to operational components, can significantly extend the lifespan of the mill. This reliability fosters confidence among manufacturers, knowing their rolling process will remain uninterrupted and efficient. In conclusion, the 3-high rolling mill is much more than just a piece of equipment; it is an embodiment of engineering ingenuity that enhances productivity, precision, and profitability in metalworking industries worldwide. Leveraging its advantages requires a balance between technical knowledge and practical application, skills that can only be honed through experience and dedication to the field. As the industry progresses, staying abreast with advances in rolling technologies is essential in maintaining competitiveness and meeting the ever-evolving demands of the market.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products