دستگاه نورد فولادی

Fév . 02, 2025 00:39

Back to list

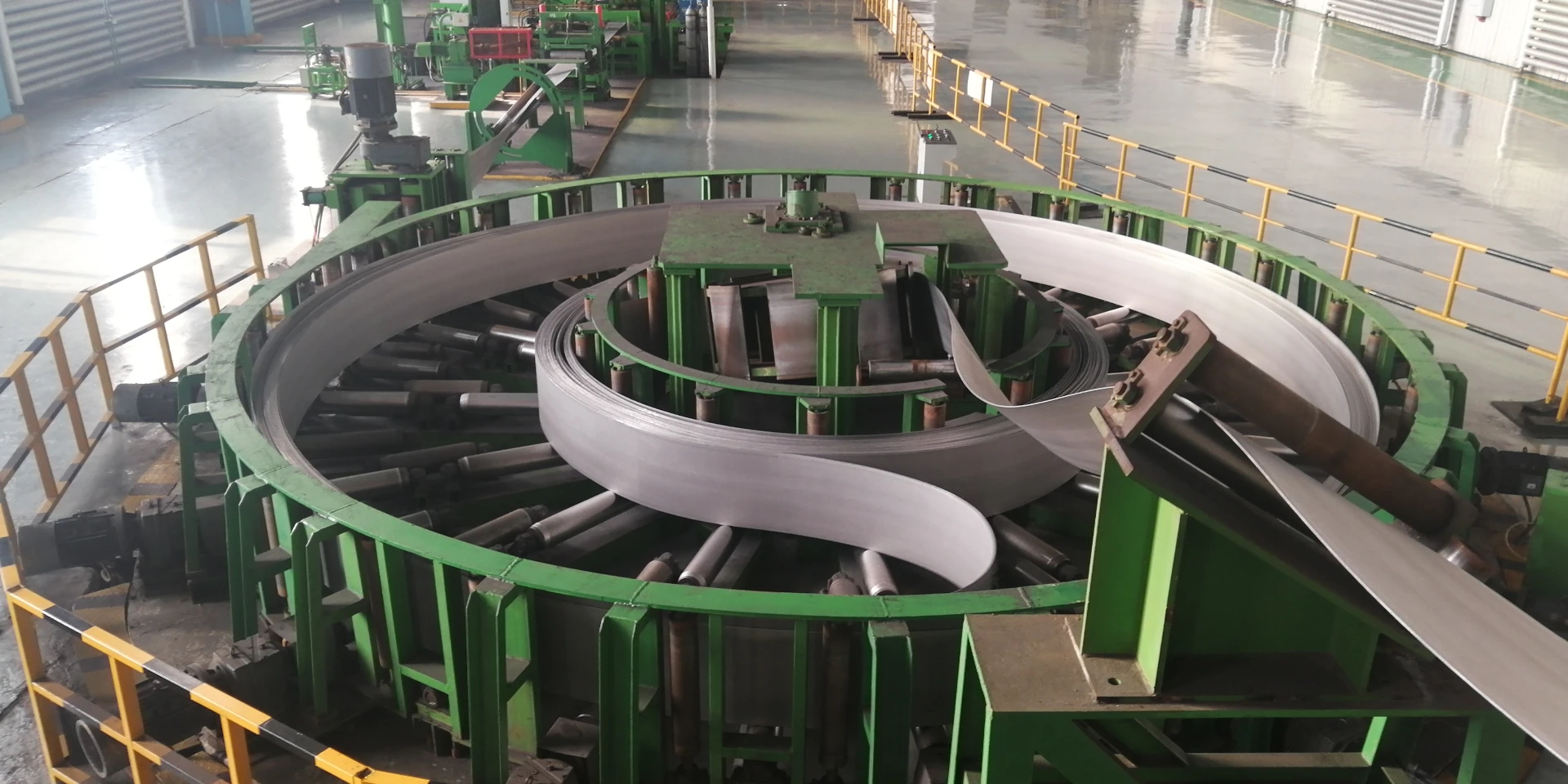

دستگاه نورد فولادی

Steel rolling machines play a crucial role in the metalworking industry, contributing to the efficient production of metal sheets, bars, and other products. With a rich history and an ever-evolving advancement in technology, these machines have transformed the steel production landscape considerably.

Steel rolling machines also stand at the forefront of addressing a global thrust for efficiency through automation. Automation in steel rolling noticeably decreases the labor intensity traditionally associated with metalworks. Operators can manage several machines simultaneously, focusing solely on quality assurance as the machines handle repetitive tasks effortlessly. This shift reduces burdens while enhancing skill sets necessary to handle sophisticated machinery. Notably, quality control is of essence when selecting a steel rolling machine. Manufacturer reputation aside, the machine's specifications must align with production goals. This includes examining power requirements, potential output, and the flexibility of adjusting rolling speeds or pressure according to material thickness or type. Partnering with seasoned suppliers is another core dimension of ensuring reliability in steel rolling operations. These suppliers typically provide rigorous training programs as part of their services, equipping clients with essential skills for operational success. This investment in customer education not only reinforces operational efficiency but extends the machine's lifecycle dramatically. Experts in the field often advise companies to consider not only the immediate needs but also future production forecasts when purchasing a machine. Scalable machines provide a degree of future-proofing, supporting business growth that aligns with increased production demands without necessitating a new capital outlay. In summary, possessing a steel rolling machine serves as a dynamic component within the manufacturing ecosystem. While innovation within the field continues at a rapid clip, focusing on a machine’s experience of use, expertise driven enhancements, established authority, and proven trustworthiness are indispensable criteria for any enterprise looking to optimize their metal production capabilities.

Steel rolling machines also stand at the forefront of addressing a global thrust for efficiency through automation. Automation in steel rolling noticeably decreases the labor intensity traditionally associated with metalworks. Operators can manage several machines simultaneously, focusing solely on quality assurance as the machines handle repetitive tasks effortlessly. This shift reduces burdens while enhancing skill sets necessary to handle sophisticated machinery. Notably, quality control is of essence when selecting a steel rolling machine. Manufacturer reputation aside, the machine's specifications must align with production goals. This includes examining power requirements, potential output, and the flexibility of adjusting rolling speeds or pressure according to material thickness or type. Partnering with seasoned suppliers is another core dimension of ensuring reliability in steel rolling operations. These suppliers typically provide rigorous training programs as part of their services, equipping clients with essential skills for operational success. This investment in customer education not only reinforces operational efficiency but extends the machine's lifecycle dramatically. Experts in the field often advise companies to consider not only the immediate needs but also future production forecasts when purchasing a machine. Scalable machines provide a degree of future-proofing, supporting business growth that aligns with increased production demands without necessitating a new capital outlay. In summary, possessing a steel rolling machine serves as a dynamic component within the manufacturing ecosystem. While innovation within the field continues at a rapid clip, focusing on a machine’s experience of use, expertise driven enhancements, established authority, and proven trustworthiness are indispensable criteria for any enterprise looking to optimize their metal production capabilities.

Latest news

-

Full- throttle! YWLX's Intense Production During May DayNewsMay.01,2025

-

Mechanical, Electrical and Hydraulic Spare Parts: Guardians of Equipment's Normal OperationNewsApr.25,2025

-

Temper Mill: An Indispensable Asset in Pickling LinesNewsApr.24,2025

-

The Role of Temper Mill in Annealing Line ApplicationsNewsApr.22,2025

-

Temper Mill: Key Element in Bright Annealing Line OperationsNewsApr.22,2025

-

Temper Mill: Crucial for Pickling Line EfficiencyNewsApr.22,2025

-

Temper Mill: An Integral Part of the Bright Annealing LineNewsApr.22,2025

Related Products