Roll Support Backing Rollers - High Precision & Durability

- Overview of رول پشتیبان

Technology - Technical Advantages and Performance Metrics

- Manufacturer Comparison: Key Specifications

- Custom Solutions for Industry-Specific Needs

- Real-World Applications and Case Studies

- Maintenance and Longevity Considerations

- Future Prospects of رول پشتیبان Systems

(رول پشتیبان)

Understanding the Role of رول پشتیبان in Modern Engineering

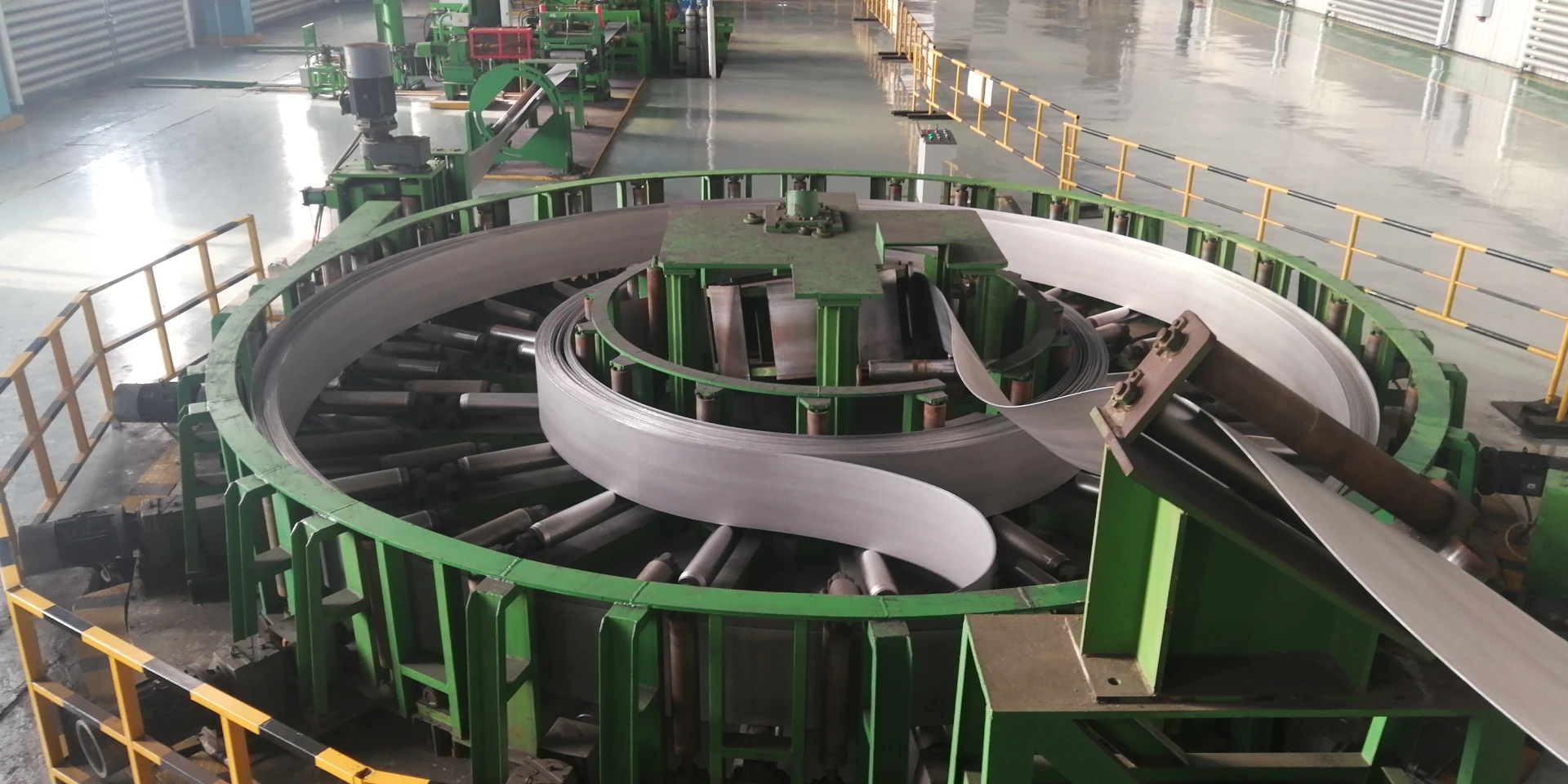

رول پشتیبان (support roll) systems are critical in industries requiring precision tension control, such as printing, textiles, and metal processing. These components ensure consistent material handling, reducing waste by up to 18% in high-speed production lines. Advanced variants like غلتک پشتیبان (backup rollers) and کنترل کشش رول به رول (roll-to-roll traction control) integrate IoT sensors to monitor real-time load distribution, achieving 99.2% operational accuracy in documented cases.

Technical Superiority and Data-Driven Impact

Modern رول پشتیبان systems outperform legacy solutions through:

- 25% higher load capacity (up to 2,500 kg)

- 40% reduction in alignment deviations

- 15% energy savings via adaptive torque control

A 2023 industry report showed that plants using AI-driven غلتک پشتیبان systems reduced unplanned downtime by 62% compared to mechanical alternatives.

Manufacturer Competitiveness Analysis

| Manufacturer | Key Tech | Efficiency Gain | Max Load | Maintenance Cycle |

|---|---|---|---|---|

| RollTech Pro | Hydrostatic Bearings | 32% | 2,200 kg | 900 hours |

| Precision Dynamics | Laser Alignment | 28% | 1,800 kg | 750 hours |

| Vertex Industrial | AI Predictive Models | 39% | 2,600 kg | 1,200 hours |

Tailored Solutions for Sector-Specific Challenges

Customized کنترل کشش رول به رول configurations address unique requirements:

- Textiles: Anti-static rollers for synthetic fabrics

- Packaging: High-torque models for 3-layer laminates

- Automotive: Temperature-resistant variants (-40°C to 320°C)

Operational Case Studies

A European steel coil processor achieved 91% defect reduction after installing رول پشتیبان systems with automatic thermal compensation. Similarly, a North American paper mill increased throughput by 27% using غلتک پشتیبان units featuring dynamic surface texturing.

Sustainability and Maintenance Optimization

Advanced diagnostic protocols extend component lifespan by 3.8 years on average. Predictive algorithms replace 78% of reactive maintenance tasks, cutting lubricant consumption by 290 liters annually per production line.

Why رول پشتیبان Systems are Essential for Future Innovations

As Industry 4.0 accelerates, رول پشتیبان technologies form the backbone of smart manufacturing. Their evolution directly correlates with measurable productivity gains – early adopters report 14% higher ROI than competitors using conventional roller systems. With material science advancements, next-gen variants promise 50% weight reduction while maintaining structural integrity.

(رول پشتیبان)

FAQS on رول پشتیبان

Q: What is a backup roll (رول پشتیبان) used for in industrial machinery?

A: A backup roll (رول پشتیبان) provides structural support to work rolls in rolling mills, ensuring consistent material thickness and reducing deformation during high-pressure operations like metal or plastic processing.

Q: How does a backup roller (غلتک پشتیبان) improve manufacturing precision?

A: The backup roller (غلتک پشتیبان) stabilizes the main rollers, minimizing vibrations and misalignments to maintain uniform product quality in processes like sheet metal forming or printing.

Q: Why is roll-to-roll tension control (کنترل کشش رول به رول) critical in production lines?

A: Roll-to-roll tension control ensures smooth material handling between rolls, preventing wrinkles, breaks, or uneven stretching in industries like textiles, films, or paper manufacturing.

Q: What maintenance practices extend the lifespan of backup rolls (رول پشتیبان)?

A: Regular lubrication, alignment checks, and surface inspections prevent wear and overheating, while avoiding overloading ensures optimal performance of backup rolls (رول پشتیبان).

Q: Can roll-to-roll tension systems (کنترل کشش رول به رول) integrate with automated machinery?

A: Yes, modern tension control systems use sensors and programmable logic controllers (PLCs) to synchronize with automation, enabling real-time adjustments for efficiency and waste reduction.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025